If you want to save energy and money, you need an automatic power factor controller. About 60% of factories and businesses use these devices. They help keep power good and stop extra charges. More places need help with power now, so a new controller like the Sinava Power SNA-PFC makes things easy. You just do these steps: get ready, put it in, set it up, use it, and take care of it. Always be safe, check your system a lot, and follow the directions for the best results.

Key Takeaways

Always make safety the most important thing when you install an automatic power factor controller. Turn off the power first and wear safety gear to stop accidents from happening.

Pick a good spot for the controller inside the electrical panel. Make sure the spot is clean and dry. Mount the controller tightly so it works well.

Set the target power factor between 0.95 and 1.00. This helps save energy and stops extra charges from the utility company. Change the settings if your electrical load changes.

Check your system often with the controller’s touch screen. Look for alerts and change settings to keep things working well.

Do regular maintenance every few months. Look at the capacitors, clean the contactors, and test the relays. This helps your system work smoothly.

Preparation

Safety

When you get ready to put in an automatic apfc, safety is most important. You work with electricity, so you must follow strict safety rules. Always turn off the power before you begin. This step keeps you safe from getting shocked or burned. You need to wear the right personal protective equipment every time you work with electrical panels. Here are the things you should use:

Rubber gloves and leather gloves for protection

Shoes that protect you from electrical danger

Hard hat with Class F or E rating

Safety glasses or goggles for your eyes

Rubber sleeves for your arms

No jewelry or metal things on you

If you work where there is a lot of energy, you need arc-rated PPE. The NFPA 70E standard helps you choose the right safety gear. You also need to check the safety rules for your equipment. Here is a quick look at the main rules for automated power factor controllers:

| UL Standard | Description |

|---|---|

| UL 810 | For power factor correction units up to 600 V, for capacitors. |

| UL 508 | For units with automatic or circuit controls, keeps industrial equipment safe. |

You should also look for certifications before you start. These show your equipment meets safety and quality rules.

| Certification | Description |

|---|---|

| ISO 45001:2018 | Health and Safety at Work |

| ISO 27001:2022 | Information Security |

| ISO 14001:2015 | Environmental Management |

| ISO 27019:2017 | Security for energy utilities |

| ISO 9001:2015 | Quality inside the company |

| NTS631 V2.0 | For UNITY SCADA/PPC |

| ISO 27017:2015 | Security for UNITY Cloud Services |

Tools

You need the right tools to work with electrical panels and put in the Sinava Power SNA-PFC. Here are the tools you should have:

Insulated screwdrivers and pliers

Wire strippers and cutters

Multimeter to test electricity

Torque wrench for tight connections

Labeling machine for wires

Shielded cables for long wires

Mounting hardware for the controller

User manual to help you

You should always keep your tools clean and in good shape. Clean tools help you stay safe from electrical problems. When you have the right tools and safety gear, you can put in automated power factor controllers with confidence.

Installation

Panel Connection

First, pick a good spot for your automatic apfc. The SNA-PFC controller goes inside the electrical panel. Make sure the panel is clean and dry. Find a space with room for the controller and wires. The SNA-PFC uses a universal LC compensation system. It works with many electrical setups. You can connect up to 24 compensation steps. This lets you adjust the system for your needs.

Check that the power is off before you start. Use insulated tools to open the panel. Mount the controller with the hardware it comes with. The 5-inch touch screen should face you. This makes it easy to see. Make sure the controller is tight and not loose. If you hurry, you might have problems later.

Tip: Always check the mounting screws two times. Loose screws can cause bad power correction. They can even start a fire.

Wiring

Wiring is a big part of installing an apfc. You need to connect the controller to the electrical system. Use shielded cables for long wires. This stops interference and keeps things working well. Keep power cables and signal cables apart. Twisted pair cables help lower electrical noise. Shorter cables are better. If you need long cables, route them carefully.

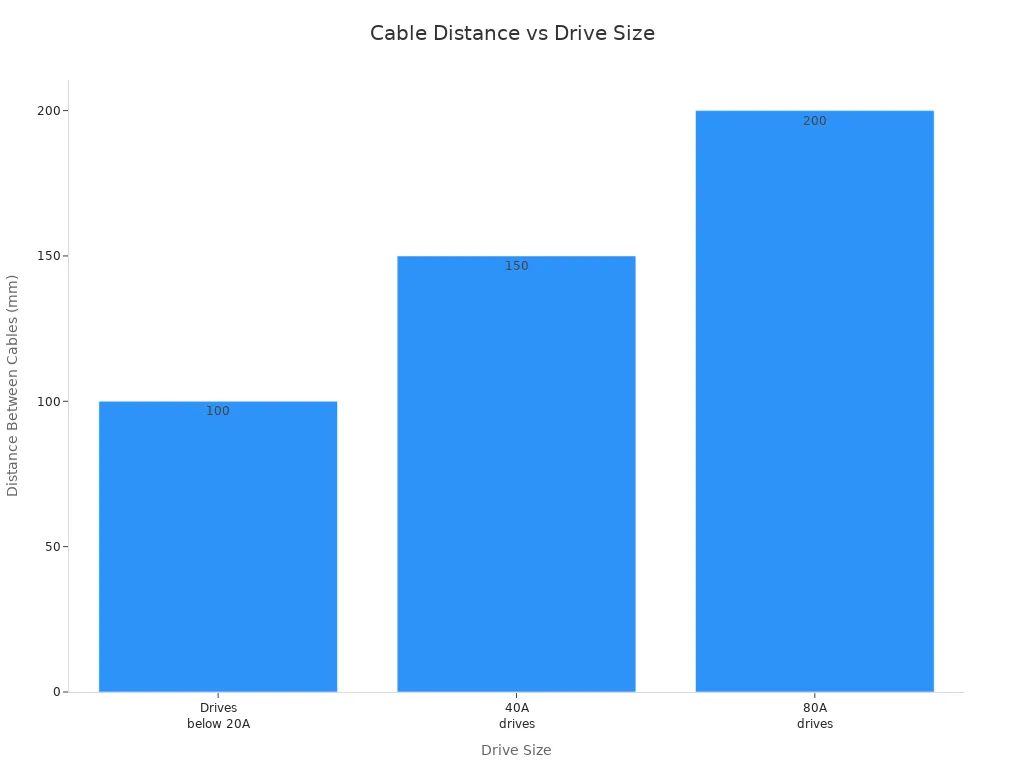

Here’s a table to help with cable distances:

| Recommendation | Distance Between Cables |

|---|---|

| For drives below 20 Amps | At least 100 mm (4") |

| For 40 Amp drives | At least 150 mm (6") |

| For 80 Amp drives | At least 200 mm (8") |

Try not to make common mistakes when you install. Watch out for these things:

Harmonics can make equipment wear out faster.

Loose connections can make power correction worse.

Wrong capacitor bank size can waste energy.

Blown fuses or bad capacitors can break the system.

Not knowing the electrical system can cause mistakes.

Note: Always check connections and parts before you finish. Regular checks help stop failures and keep your automatic apfc working well.

Setup & Programming

Automatic Power Factor Controller Settings

When you set up your automatic power factor controller, you need to decide what you want your system to do. The SNA-PFC gives you a touch screen to make this easy. You start by choosing your target power factor. This is the number that shows how well your electrical system uses energy. Most factories and businesses pick a target power factor between 0.95 and 1.00. This helps you save money and avoid extra charges from your utility company.

You also need to set up the number of steps for your controller. The SNA-PFC lets you use up to 24 steps. Each step controls a part of your capacitor bank. You can match the steps to your electrical load. This means your automatic apfc can add or remove power factor correction as your needs change. You want to make sure each step fits the size of your electrical loads.

Here’s what you set on the controller:

Target power factor (like 0.98)

Number of steps (up to 24)

Size of each step (in kVAR)

Delay time between steps

Alarm settings for electrical faults

Tip: Always check your electrical drawings before you enter these settings. This helps you match the controller to your real system.

Frequency & Parameters

You also need to set the frequency for your electrical system. Most places use either 50Hz or 60Hz. The SNA-PFC lets you pick the right one for your country or region. If you pick the wrong frequency, your power factor correction will not work right.

Next, you set other important parameters. These help your automatic power factor controller work with your electrical system. You can set things like:

Voltage and current transformer ratios

Minimum and maximum power factor limits

Alarm thresholds for electrical problems

Step switching time (how fast the controller adds or removes steps)

Type of compensation (like LC for inductive or capacitive loads)

Here’s a table to help you see what you need to set:

| Parameter | What It Does | Example Value |

|---|---|---|

| Target Power Factor | Sets your goal for power factor | 0.98 |

| Frequency | Matches your electrical system | 50Hz/60Hz |

| Number of Steps | Controls how many steps you use | 12 |

| Step Size | Sets kVAR for each step | 25 kVAR |

| Alarm Threshold | Warns you about electrical faults | 0.90 |

| Switching Time | Time between step changes | 30 seconds |

Note: If you set the parameters right, your electrical system will run better and your power factor will stay close to your target.

You can use the touch screen to check your settings at any time. The SNA-PFC shows you real-time data about your electrical loads and power factor. If you see a problem, you can change the settings right away. This keeps your system safe and efficient.

Operation

Monitoring

When you use an automatic power factor controller like the SNA-PFC, you can see your electrical system clearly. The touch screen shows power factor readings as they happen. You watch how your electrical loads change all day. The controller shows voltage, current, and step status. You check the screen to see if your power factor is near your target.

The controller updates every few seconds. You see graphs and numbers for each compensation step. You notice which steps are working and which are not. You look for quick changes in electrical demand. The controller helps you see how much reactive power is fixed.

You find alerts and icons on the screen. You see if the system works well or if there is a warning. You check the log to see past events. You use monitoring to keep your electrical system steady. You check often to find problems early. You change settings if your power factor moves away from your goal.

Tip: You get better results when you check your automatic power factor controller often. You find problems before they hurt your electrical system.

Alerts

You see alerts when something strange happens in your electrical system. The SNA-PFC shows alarms for different electrical problems. You get warnings for things like high device latency, port errors, or loss of signal. You notice how serious each alert is. Some alarms need fast action, while others go away after a short time.

Here’s a table showing what alerts you might see and what they mean:

| Alarm Type | Severity | Description | Clearing Method |

|---|---|---|---|

| RxTx Alarm | Warning | Triggered by violations in Rx or Tx measures. | Manual, auto-clear after 30 minutes of idle time. |

| Oversubscription Alarm | Major | Triggered when PORT_BANDWIDTH measure is violated. | Manual, auto-clear upon receiving clear signal. |

| Utilization Alarm | Warning | Triggered by violations in UTIL measure. | Manual, auto-clear after 30 minutes of idle time. |

| Port Error Alarm | Warning | Triggered by port error measures. | Manual. |

| Link Alarm | Warning | Triggered by link fault measures. | Manual. |

| Loss of Signal Alarm | Warning | Triggered by loss of signal. | Manual. |

| SFP Alarm | Warning | Triggered by SFP measures. | Manual. |

| Device Latency Alarm | Major | Triggered by device latency impact. | Manual, auto-clear upon receiving clear signal. |

You check alert details on the touch screen. You see which part of your electrical system needs help. You clear alarms by hand or wait for the controller to reset them. You watch major alarms because they can change your power factor correction. You use the log to look at old alerts and find patterns.

You make changes to keep your power factor near your target. You replace broken parts if you see the same alarms often. You use alerts to keep your electrical system safe and working well. You notice that checking often and acting fast helps you save energy.

Note: You see more alerts when your electrical system has heavy loads or quick changes. You act fast to keep your automatic power factor controller working well. You handle more power needs by staying alert and ready.

Maintenance

Routine Checks

You want your automatic power factor controller to work well for years. Doing regular maintenance is very important. If you follow a good schedule, your electrical system stays safe and works better. Most controllers like the Sinava Power SNA-PFC last 7 to 10 years if you take care of them.

Here are some things you should do often:

Look at the capacitors. Check for damage and measure capacitance and insulation resistance.

Clean the contactors. Remove dust and look for rust or worn spots.

Test the relays. Use a power factor meter to see if they work right.

Oil the fans. Clean them and add oil if they need it.

Watch the harmonics. Use a power quality analyzer to find strange signals.

Check the settings. Change them if your electrical load is different.