Have you ever thought about why your factory pays so much for energy? Sometimes machines stop working without warning. These problems happen because power quality can affect your work. A custom Capacitor Bank helps fix these issues. Smart systems let you change power factor correction quickly. This saves energy and money. Real-time monitoring helps prevent outages. It keeps your production going without trouble. You need a solution made for your factory. A one-size-fits-all choice will not work well.

Key Takeaways

Custom Capacitor Banks help fix power factor. This means less energy is wasted. It also helps lower your electric bills.

Custom solutions keep voltage steady. This protects equipment that can break easily. Machines last longer and break down less.

Special designs let factories grow in the future. You can add more capacity easily. You do not need expensive upgrades.

Checking and taking care of capacitor banks often stops outages. It helps them work their best.

Picking a custom solution is better than a standard one. It lowers risks and makes your factory work better.

Role in Factories

Power Factor Correction

Factories want to work well and save money. Power factor correction helps with this. Machines like motors and transformers use two kinds of power. If the power factor is low, energy gets wasted. You pay more to the utility company. A custom Capacitor Bank stores and gives out reactive power when needed. This lowers what you need from the utility. It makes your system work better.

Here is a table that shows why power factor correction is important for your factory:

| Function/Benefit | Description |

|---|---|

| Power Factor Correction | Stores reactive power, reducing utility demand and boosting efficiency. |

| Efficiency Improvement | Lowers losses in the system, making your operations smoother. |

| Cost Savings | Reduces demand charges and extends equipment life. |

| Stability | Keeps voltage levels steady, lowering the risk of spikes or sags. |

You can put capacitors next to your machines. This helps with reactive power needs and raises your power factor. When you make your power factor better, you also:

Waste less energy as heat.

Use more real power for making products.

Have fewer surprise shutdowns.

A custom Capacitor Bank matches your system’s needs. You do not get problems from generic solutions that do not fit your factory.

Voltage Support

Steady voltage keeps machines safe and working well. If voltage goes down or changes a lot, equipment can get too hot or stop. Capacitor banks give reactive power where it is needed. This helps fix voltage drops and keeps machines in the right range.

Here is a table that shows how capacitor banks help with voltage support:

| Function | Description |

|---|---|

| Voltage Regulation | Supplies reactive power to fix voltage drops and keep machines running well. |

| Power Factor Improvement | Compensates for inductive loads, making your system more efficient. |

| Reduction of System Losses | Cuts down on wasted energy in your distribution system. |

| Stability of Power Quality | Filters out voltage swings, protecting sensitive equipment. |

A custom Capacitor Bank gives voltage support made for your factory. You get fewer stops, less damage to machines, and better performance.

Standard vs. Custom Capacitor Bank

Limitations of Standard Options

Standard capacitor banks look simple to use. But they can cause hidden trouble. You might hear odd sounds or see blown fuses. Sometimes, machines stop working all of a sudden. These problems happen because standard units do not fit every factory. Harmonic currents can make the capacitor work too hard. This makes it get hotter inside and can break it. You might see the capacitor bulge or even burst. Too much voltage or current can make it explode. When a standard capacitor bank gets old, it can fail in risky ways. You could see sparks or even a fire. These issues can stop your work and cost you money.

Note: Harmonic problems often show up first in shunt capacitor banks. You may hear noise or see blown fuses before a bigger failure happens.

Why Customization Matters

You need a solution made for your factory. A custom Capacitor Bank fits your needs. Every factory has different machines and plans. Off-the-shelf products do not match these needs. Custom banks help you plan for the future. You can add more power now and skip big upgrades later. This saves you lots of money over time.

Here is a table that shows why customization matters:

| Factor | Explanation |

|---|---|

| Unique Operational Needs | Custom banks match your factory’s load profile for better efficiency. |

| Future Growth Considerations | Planning for extra capacity now prevents costly changes later. |

| Specific Electrical Needs | Tailored designs solve problems that standard units cannot handle. |

Custom banks are easier to fix. Side-mounted units with front access help repairs go faster. You spend less on new parts. Custom banks do not have hard-to-fix designs. When you pick a custom solution, your capacitor bank helps you. It does not cause problems for you.

custom Capacitor Bank Benefits

Tailored Solutions

You need a solution that fits your factory’s needs. Every factory uses different machines and has its own work style. A custom Capacitor Bank gives you choices that match what you need. You can pick from these types: Pole-mounted, Metal-enclosed, Mobile, Open air, and Specialty application. These choices help you put the right system in your space. You can also add things like switches, PTs, and kits. This makes your setup simple and strong. For example, one aluminum factory had trouble with power. Their power factor was too low. Experts looked at their work and made a special plan. They used special switches and reactors. This fixed their power problems and helped them work better.

Tip: Custom solutions fix problems that standard products cannot. You get a system made for your factory, not just a basic fix.

Energy Efficiency

You want to use less energy and save money. A custom Capacitor Bank helps you do this. When you use a system made for your factory, you make your power factor better. This means you waste less energy. At a foundry in the Midwest, custom capacitor banks saved lots of energy. The factory paid less for power and worked better. You can see these changes in your own factory too. Lower energy bills, Better use of electrical power, and Fewer losses in your system are some benefits. Custom banks also help with renewable energy. They keep the grid balanced and power quality high, even when solar or wind changes.

Equipment Protection

Sensitive machines need steady voltage and clean power. Custom capacitor banks keep your machines safe from voltage swings and harmonics. They hold voltage steady and clean up the power. This stops problems and helps your machines last longer. Capacitors also help with non-linear loads, like variable frequency drives. You get cleaner power and better machine performance.

Note: Protecting your equipment means fewer repairs and less downtime. Your machines last longer and work safer.

Scalability

Factories grow and change over time. You need a system that can grow with you. Custom Capacitor Banks give you choices for voltage, capacitance, and how you connect them. Here is a table that shows how these banks help your future plans:

| Feature | Details |

|---|---|

| Voltage Options | Common options: 12V, 24V, 48V, 72V |

| Capacitance Range | 30F to 21,000F |

| Temperature Tolerance | -40°C to +65°C operational range |

| Cycle Life | >500,000 cycles for automotive applications |

| Compliance Standards | IEC 62391 and UL 810A |

| Integration Capabilities | CAN bus communication for easy integration |

You can add more power or new parts as you grow. This saves money and stops you from needing big upgrades.

Compliance

You must follow energy rules and standards. Custom Capacitor Banks help you do this by making power better and more efficient. They cut down on voltage changes and harmonic distortion. Your system works better and uses less current. Accessories and kits make it easier to follow safety and performance rules. Improved power quality, Increased efficiency, and Easier compliance with standards are some benefits. You should check your system often. Look at capacitors, watch for heat, control voltage, and change old parts. Use sealed units and coatings to protect your equipment from tough places.

Impact

Efficiency Gains

You want your factory to work well and not waste energy. When you add a custom Capacitor Bank, your machines run better. You waste less energy and get more steady power. Many factories see big changes after using these banks.

Here is a table that shows how companies got better after adding capacitor banks:

| Company Name | Implementation Details | Energy Reduction | Annual Cost Savings |

|---|---|---|---|

| ABC Manufacturing | Installed capacitor banks and harmonic filters | 15% | $75,000 |

| XYZ Corp | Upgraded motors and installed variable frequency drives | 25% | Significant maintenance savings |

Your equipment lasts longer and breaks down less. Machines get steady voltage, so they do not stop as much. Power quality also gets better. For example, car factories used capacitor banks with AC drive systems. This cut down on harmonic distortion by 30%. They used 15% less energy and their machines lasted longer.

Custom capacitor banks help block bad harmonics. They keep voltage steady and protect sensitive machines. You get more stable power, so things do not overheat or break.

Tip: Check your capacitor banks often. This stops downtime and keeps your factory working well.

Cost Savings

Saving money matters for every factory. Custom Capacitor Banks lower your energy bills and cut repair costs. You do not pay extra for bad power factor. You also have fewer surprise shutdowns.

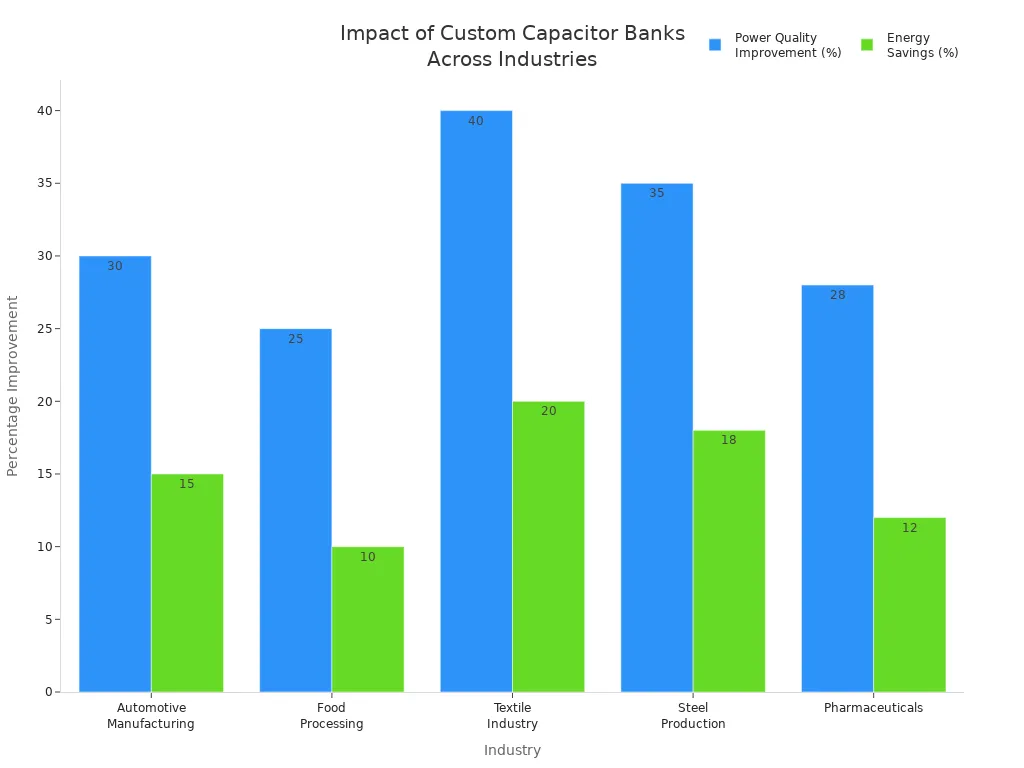

Here is a table that shows how different industries save money with custom capacitor banks:

| Industry | Application | Benefits | Power Quality Improvement (%) | Energy Savings (%) |

|---|---|---|---|---|

| Automotive Manufacturing | AC Drive Systems | Enhanced lifespan, less distortion | 30% | 15% |

| Food Processing | Refrigeration Systems | Better power factor, lower energy costs | 25% | 10% |

| Textile Industry | Weaving Machines | Stable voltage, reduced downtime | 40% | 20% |

| Steel Production | Induction Furnaces | Efficient process, lower maintenance | 35% | 18% |

| Pharmaceuticals | HVAC Systems | Consistent control, less energy waste | 28% | 12% |

You get your money back fast. Most factories save enough in a few months to pay for the banks. You also follow energy rules more easily and avoid fines.

Note: Keep your capacitor banks in good shape. This stops overheating and failures. Your factory keeps running and you save money.

Need Assessment

Key Indicators

You may wonder how to tell if your factory needs a custom capacitor bank. Certain signs show that your power system is not working as well as it should. Watch for these key indicators:

⚡ Frequent voltage drops or spikes: Machines stop or slow down when voltage changes too much.